General introduction:

| Place of Origin: | Hunan, China (Mainland) |

| Brand Name: | Phohom clad metal |

| Model Number: | cutter clad plate |

| Material: | cladding metal new materials, customized metals |

| Process Technical: | Explosion Welding |

| Application: | Industrial cutting tools |

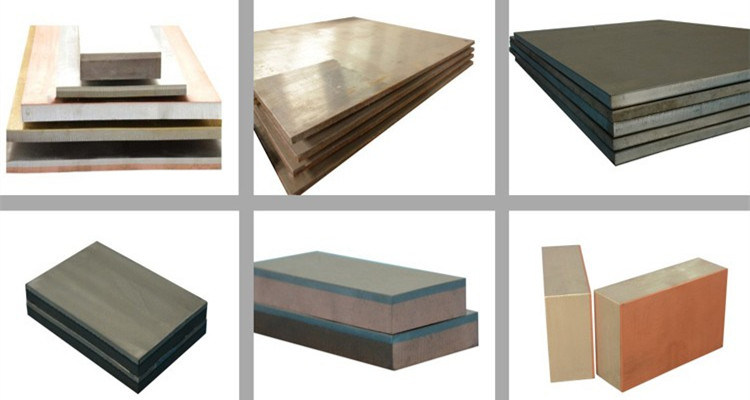

Shape: | plate, square, retangle, rod or others customized |

| Quality Control: | Upon ISO, ASTM,ASME,JIS,NB,JB |

| Size: | the cladding metal thickness 0.5-50mm; the base metal thickness: 0.5-500mm; dimension of length and width: according to customer's requirements and transportation condition |

| Bonding ability: | Shearing/Tensile strength according to ASTM standard |

Material: cladding metal new materials, excellent stainless steel ,aluminum and customized metals

Application: electrode, decoration parts of vehicles and high-speed train, vehicles' body, and heat exchangers' parts, middle and high-end kitchen ware.

Shape: plate, square, retangle, rod or others customized

Quality Control: Upon ISO, ASTM,ASME,JIS,NB,JB

Size: the cladding metal thickness 0.5-50mm; the base metal thickness: 0.5-500mm; dimension of length and width: according to customer's requirements and transportation condition

Advantage: Light Weight, Corrosion resistance, Excellent formability, High heat conductivity ,High strength ,High electric conductivity ,Strong light reflectivity ,No low - temperature brittleness ,Nuclear radiation resistance, Good absorption in impact waves, Non-magnetic, Weldable, No toxicity, Good recycling

Bonding ability: Shearing/Tensile strength according to ASTM standard

Product information

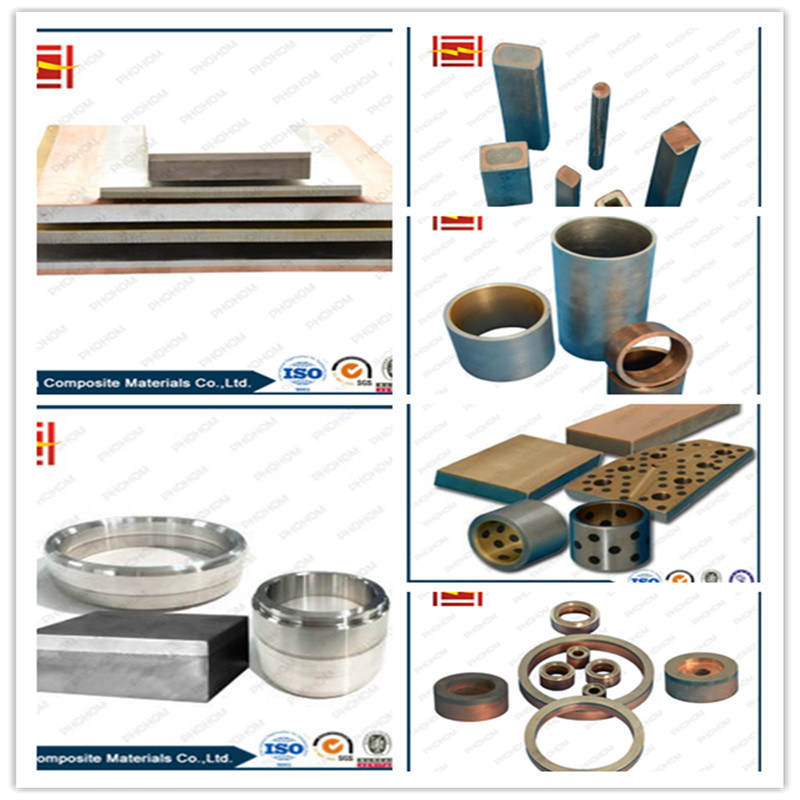

Bimetal clad cutting tools, bimetal clad industrial cutting tools

Through explosive welding, bonding high strength, high hardness, high wear-resistant special metals and general steel or stainless steel, these clad metals have combined the properties of high hardness and wear-resistance of special metals with the structure property of general steel, so this saves the precious metals, and reduces the cost, and they can also make life cutting tools, and industrial cutting tools.

Specifications

1.metallurgical combination without interlayer

2.Excellent performance

3.Thickness ratio: upon request

4.Entire interface combination

5.100% UT inspection

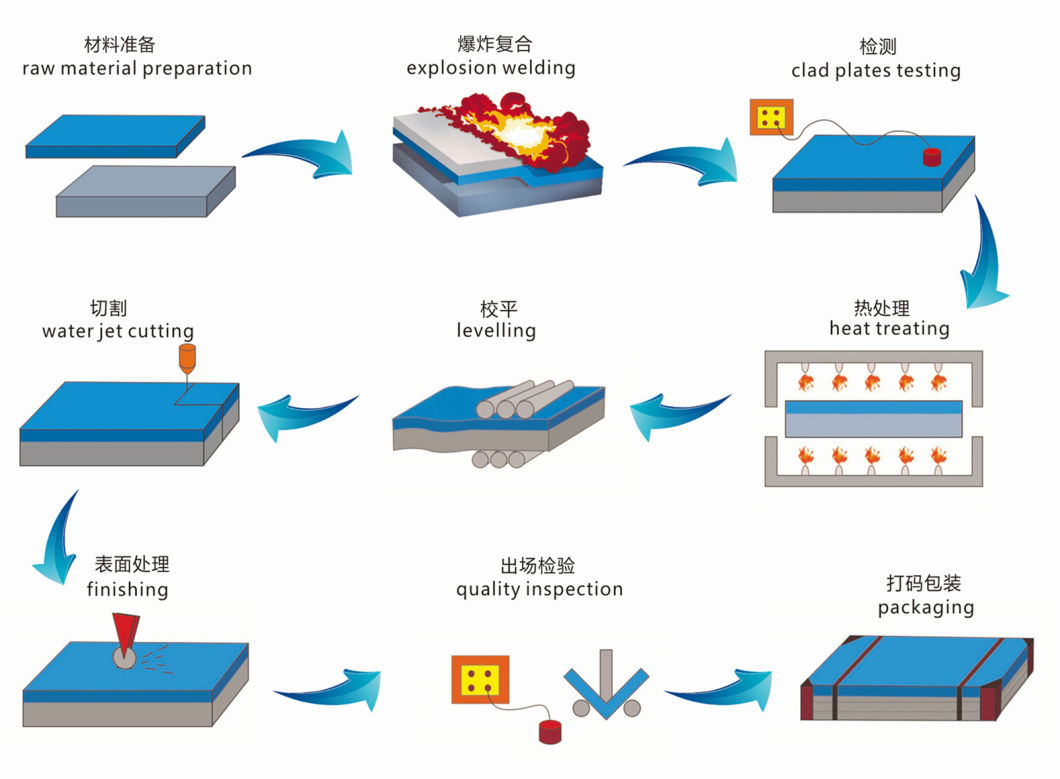

Explosion welding Introduction:

Metal dynamic clad technology (explosion welding or explosion cladding technology) uses high energy from explosive detonation to produce a metallurgical weld between metal plates. It can produce high voltage pulse energy, pushing cladder collide with backer at a specific velocity and impact angle. That process produces much bigger stress than the yield strength of metal material. All these happen at instantaneous moment and simultaneously infinitesimal adjacent area of collision point of limited loading stress of materials, realizing wavelike metallurgical weld of two materials.

Core Technology: Explosive Welding Clad; Dynamic Metals Bonding;

Audited supplier to:

CAS (Chinese Academy of Sciences)

CSNS (China Spallation Neutron Source) Project;

IHEP(Institute of High Energy Physics, Chinese Academy of Sciences);

SIONSTEEL; SINOCHEM; CSIC; AVIC;

Technical Character:

Wide range of metal combinations;

Available in various sizes, without the limits of materials sizes or forms;

Metallurgical bonding with high strength;

Fabrication of multi-laminates, metal and non-metal clad;

New method for fabrication of transition joints;

Series&Application

| Main Products: Corrosion Resistance Clad Plates; Wear Resistance Clad Plates; Clad Tube Sheets & Heads; Structure Transition Joints; Electrical Transition Joints; Cryogenic Transition Joints; Applied industries: oil&gas, petrochemical, chemical industry, aerospace, vehicle, shipbuilding, mechanical industries; Applied equipment: aluminum steel boat, tube heat exchangers, pressure vessels, boilers, tanks, aluminum smelting, etc. |

Our Customers

Audited supplier to in Chinese Markets:

CSNS (China Spallation Neutron Source) Project;

IHEP(Institute of High Energy Physics, Chinese Academy of Sciences);

SIONSTEEL; SINOCHEM; CSIC; AVIC;

Exported Countries:

Nearly 20 countries including USA, Canada, German, Espain, UK, Romania, Denmark, Japan, Korea, Australia, Indonesia,

Brazil, Venezuela and others.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: Do you accept the customization ?

A: Yes, we can customize the product according the specification.

Q: Do you provide samples ?

A: Yes, we could offer the sample according to the customer's requirements.

Q: What is your terms of payment ?

A: Payment 50 % T/T in advance ,balance before shippment.

Package&Shipping

→Package: standard export package; anticorrosion oil paper, water-proof membrane, polywood box, iron case box, or

according to customers requirements.

→Delivery time: within 30-60days according to different orders.

→Main Export Port: Shanghai, or according to customers requirements.

→Shipping Time: according to different transportation ways and ship routes.

If you have other questions, pls feel free to contact us as below:

Icey / Overseas Sales Manager

T: 0731-89719827

P: +86-185 70381140

Web: phohomnewmaterial.en.made-in-china.com

...................................................................

Hunan Phohom New Material Technology Co., Ltd.

Address: No. 328, Tongzipo West Rd., High Tech Zone, Changsha, Hunan Province, China 410017